Biodegradable potato starch trays with asparagus (Asparagus officinalis L.) stump fiber

DOI:

https://doi.org/10.51252/raa.v3i1.429Keywords:

mix design, thermoformed trays, mechanical propertiesAbstract

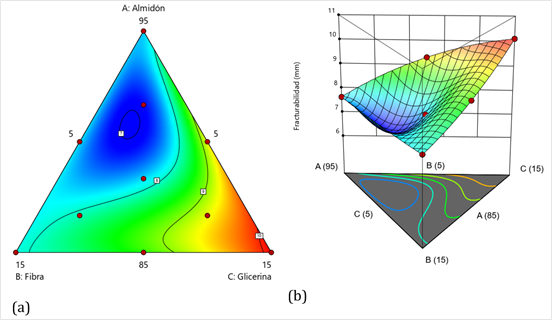

Starch-based biodegradable containers are an alternative to reduce the fraction of urban solid waste originated by the use of expanded polystyrene trays, which are generally difficult to biodegrade. In the present work, the obtaining of a biodegradable tray made of potato starch (A), asparagus stump fiber (F) and glycerin (G) was investigated in a thermoforming process with a pressure of 24 bar at 150 °C for a time of 20 minutes. Simplex Centroid Mixture Design was used to determine the amounts of the components in each treatment. The trays were characterized by physical tests (thickness and density) and mechanical tests (fracturability, hardness, tensile strength and elongation percentage). Finally, using the desirability function, it was determined that the optimum mixture for obtaining biodegradable trays was the F/A ratio of 85/6.89 and % G of 13.11 %, which maximized the values of hardness (19.19 kg), fracturability (9.09 mm), tensile strength (0.133 MPa) and elongation percentage (2.998 mm).

Downloads

References

Angulo Cueva, R. C. (2019). Potencial alimentario de productos obtenidos a partir de residuos industriales de espárrago [Universidad Nacional de Trujillo]. http://dspace.unitru.edu.pe/handle/UNITRU/14875

Barrios Córdova, A., Vaquera Huerta, H., Romero Padilla, J. M., Crossa, J., & Burguete Hernández, E. (2020). Estudio comparativo de técnicas de optimización multirespuesta en diseños experimentales. Ingeniería Investigación y Tecnología, 21(2), 1–12. https://doi.org/10.22201/fi.25940732e.2020.21n2.016

Bergel, B. F., da Luz, L. M., & Santana, R. M. C. (2017). Comparative study of the influence of chitosan as coating of thermoplastic starch foam from potato, cassava and corn starch. Progress in Organic Coatings, 106, 27–32. https://doi.org/10.1016/j.porgcoat.2017.02.010

Bolt, H. M. (2005). Vinyl Chloride—A Classical Industrial Toxicant of New Interest. Critical Reviews in Toxicology, 35(4), 307–323. https://doi.org/10.1080/10408440490915975

Cabanillas, A., Nuñez, J., Cruz-Tirado, J., Vejarano, R., Tapia-Blácido, D. R., Arteaga, H., & Siche, R. (2019). Pineapple shell fiber as reinforcement in cassava starch foam trays. Polymers and Polymer Composites, 27(8), 496–506. https://doi.org/10.1177/0967391119848187

Cinelli, P., Chiellini, E., Lawton, J. W., & Imam, S. H. (2006). Foamed articles based on potato starch, corn fibers and poly(vinyl alcohol). Polymer Degradation and Stability, 91(5), 1147–1155. https://doi.org/10.1016/j.polymdegradstab.2005.07.001

Cruz-Tirado, J. P., Siche, R., Cabanillas, A., Díaz-Sánchez, L., Vejarano, R., & Tapia-Blácido, D. R. (2017). Properties of baked foams from oca ( Oxalis tuberosa ) starch reinforced with sugarcane bagasse and asparagus peel fiber. Procedia Engineering, 200, 178–185. https://doi.org/10.1016/j.proeng.2017.07.026

Cruz-Tirado, J. P., Vejarano, R., Tapia-Blácido, D. R., Barraza-Jáuregui, G., & Siche, R. (2019). Biodegradable foam tray based on starches isolated from different Peruvian species. International Journal of Biological Macromolecules, 125, 800–807. https://doi.org/10.1016/j.ijbiomac.2018.12.111

De Jesus Rahmer, B., Garzón Saénz, H., & Solana Garzón, J. (2019). Uso de la función de deseabilidad para la optimización de un proceso de producción de poliestireno. Revista Ingeniería Industrial, 18(1), 27–42. https://revistas.ubiobio.cl/index.php/RI/article/view/4132

Espina, M., Cruz-Tirado, J. P., & Siche, R. (2016). Mechanical properties of trays based on starch of native plant species and fiber of agroindustrial wastes. Scientia Agropecuaria, 07(02), 133–143. https://doi.org/10.17268/sci.agropecu.2016.02.06

Ferreira, A. M., Martins, J., Carvalho, L. H., & Magalhães, F. D. (2019). Biosourced Disposable Trays Made of Brewer’s Spent Grain and Potato Starch. Polymers, 11(5), 923. https://doi.org/10.3390/polym11050923

Hoyos Mireles, B. J., Cieza Díaz, E. del R., & Castro Medina, R. S. (2021). Ecological trays based on banana (Musa paradisiaca) and achira (Canna indica) leaf blades: Physical, mechanical and chemical characteristics. Agroindustrial Science, 11(1), 87–96. https://doi.org/10.17268/agroind.sci.2021.01.11

Jiang, J., Gao, H., Zeng, J., Zhang, L., Wang, F., Su, T., & Li, G. (2021). Determination of subfreezing temperature and gel retrogradation characteristics of potato starch gel. LWT, 149, 112037. https://doi.org/10.1016/j.lwt.2021.112037

Kaisangsri, N., Kerdchoechuen, O., & Laohakunjit, N. (2012). Biodegradable foam tray from cassava starch blended with natural fiber and chitosan. Industrial Crops and Products, 37(1), 542–546. https://doi.org/10.1016/j.indcrop.2011.07.034

Lee, J. W., Lee, J. H., Yu, I. H., Gorinstein, S., Bae, J. H., & Ku, Y. G. (2014). Bioactive Compounds, Antioxidant and Binding Activities and Spear Yield of Asparagus officinalis L. Plant Foods for Human Nutrition, 69(2), 175–181. https://doi.org/10.1007/s11130-014-0418-9

Miléo, P. C., Oliveira, M. F., Luz, S. M., Rocha, G. J. M., & Gonçalves, A. R. (2016). Thermal and chemical characterization of sugarcane bagasse cellulose/lignin-reinforced composites. Polymer Bulletin, 73(11), 3163–3174. https://doi.org/10.1007/s00289-016-1647-x

Ruiz Quispe, G. F. (2018). Propuesta de mejora de métodos de trabajo en el proceso de producción de espárrago verde fresco para incrementar la productividad de la asociación agrícola Compositan Alto [Universidad Privada del Norte]. https://hdl.handle.net/11537/13349

Salgado, P. R., Schmidt, V. C., Molina Ortiz, S. E., Mauri, A. N., & Laurindo, J. B. (2008). Biodegradable foams based on cassava starch, sunflower proteins and cellulose fibers obtained by a baking process. Journal of Food Engineering, 85(3), 435–443. https://doi.org/10.1016/j.jfoodeng.2007.08.005

Sarabi, B., Hasandokht, M., Hassani, M., & Masoomi, T. (2010). Evaluation of Morphological Characteristics of Iranian Edible Wild Asparagus (Asparagus officinalis L.). Iranian Journal of Horticultural Science, 41(3), 372312. https://ijhs.ut.ac.ir/article_21914.html?lang=en

Sinha, N. K. (2011). Handbook of Vegetables and Vegetable Processing (5th ed.). Blackwell Publishing Ltd.

Vercelheze, A. E. S., Fakhouri, F. M., Dall’Antônia, L. H., Urbano, A., Youssef, E. Y., Yamashita, F., & Mali, S. (2012). Properties of baked foams based on cassava starch, sugarcane bagasse fibers and montmorillonite. Carbohydrate Polymers, 87(2), 1302–1310. https://doi.org/10.1016/j.carbpol.2011.09.016

Wang, W., Chen, W., Yang, H., & Cui, M. (2017). Textural and rheological properties of potato starch as affected by amino acids. International Journal of Food Properties, 20(sup3), S3123–S3134. https://doi.org/10.1080/10942912.2017.1396475

Waterschoot, J., Gomand, S. V., Fierens, E., & Delcour, J. A. (2015). Production, structure, physicochemical and functional properties of maize, cassava, wheat, potato and rice starches. Starch - Stärke, 67(1–2), 14–29. https://doi.org/10.1002/star.201300238

Zhang, Z., Yao, Y., Shi, Q., Zhao, J., Fu, H., & Wang, Y. (2020). Effects of radio-frequency-assisted blanching on the polyphenol oxidase, microstructure, physical characteristics, and starch content of potato. LWT, 125, 109357. https://doi.org/10.1016/j.lwt.2020.109357

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Elmer Diaz-Diaz, Celestino Cabrera-Guevara, Yorly Diaz-Idrogo, Julio Santiago Chumacero-Acosta, Pedro Wilfredo Gamboa-Alarcon

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors retain their rights:

a. The authors retain their trademark and patent rights, as well as any process or procedure described in the article.

b. The authors retain the right to share, copy, distribute, execute and publicly communicate the article published in the Revista Agrotecnológica Amazónica (RAA) (for example, place it in an institutional repository or publish it in a book), with an acknowledgment of its initial publication in the RAA.

c. Authors retain the right to make a subsequent publication of their work, to use the article or any part of it (for example: a compilation of their works, notes for conferences, thesis, or for a book), provided that they indicate the source of publication (authors of the work, journal, volume, number and date).