Characteristics of biodegradable trays of potato (Solanum phureja) starch reinforced with yellow corn (Zea mays L.) and white asparagus (Asparagus officinalis) stump

DOI:

https://doi.org/10.51252/reacae.v2i1.430Keywords:

biopolymers, biodegradable packaging, tensile testing, compression testingAbstract

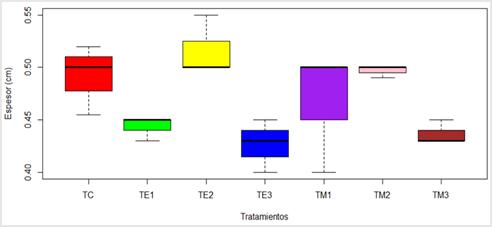

Biodegradable trays seek to be an alternative solution to the environmental problems caused by the accumulation of plastics. The objective of this work was to evaluate the effect of the addition of white asparagus stump fiber and yellow corn stover fiber on the mechanical properties of potato starch-based biodegradable trays. Three starch/fiber ratios (95/5; 90/10 and 85/15) were used and physical characteristics (thickness and density) and mechanical properties (tensile strength, elongation, strength and fracture) were evaluated. The results showed the 85/15 corn starch/fiber ratio treatment as the one that presented the best expansion with fibers, tensile strength of 0.2132 MPa and elongation of 1.58%, as well as resistance to the hardness test of 17.29 kg and 2.64 mm of fracturability. These results obtained could demonstrate the alternative to the use of polystyrene foam trays.

Downloads

References

Aguiar Conya, S. A., García Veloz, M. J., & Vallejo Abarca, S. M. (2020). Diseño y elaboración de utensilios biodegradables a partir de la fibra del tallo de banano (Musa paradisiaca) como alternativa de uso para mitigar impactos ambientales causados por el plástico. Ciencia Digital, 4(1), 373–384. https://doi.org/10.33262/cienciadigital.v4i1.1118

Alvarado, S., Sandoval, G., Palos, I., Tellez, S., Aguirre-Loredo, Y., & Velazquez, G. (2015). The effect of relative humidity on tensile strength and water vapor permeability in chitosan, fish gelatin and transglutaminase edible films. Food Science and Technology, 35(4), 690–695. https://doi.org/10.1590/1678-457X.6797

Asim, M., Abdan, K., Jawaid, M., Nasir, M., Dashtizadeh, Z., Ishak, M. R., & Hoque, M. E. (2015). A Review on Pineapple Leaves Fibre and Its Composites. International Journal of Polymer Science, 2015, 1–16. https://doi.org/10.1155/2015/950567

Aygün, A., Uslu, M. K., & Polat, S. (2017). Effects of Starch Sources and Supplementary Materials on Starch Based Foam Trays. Journal of Polymers and the Environment, 25(4), 1163–1174. https://doi.org/10.1007/s10924-016-0886-0

Cabanillas, A., Nuñez, J., Cruz-Tirado, J., Vejarano, R., Tapia-Blácido, D. R., Arteaga, H., & Siche, R. (2019). Pineapple shell fiber as reinforcement in cassava starch foam trays. Polymers and Polymer Composites, 27(8), 496–506. https://doi.org/10.1177/0967391119848187

Chaireh, S., Ngasatool, P., & Kaewtatip, K. (2020). Novel composite foam made from starch and water hyacinth with beeswax coating for food packaging applications. International Journal of Biological Macromolecules, 165, 1382–1391. https://doi.org/10.1016/j.ijbiomac.2020.10.007

Cruz-Tirado, J. P., Tapia-Blácido, D. R., & Siche, R. (2017). Influence of Proportion and Size of Sugarcane Bagasse Fiber on the Properties of Sweet Potato Starch Foams. IOP Conference Series: Materials Science and Engineering, 225, 012180. https://doi.org/10.1088/1757-899X/225/1/012180

Cruz-Tirado, J. P., Vejarano, R., Tapia-Blácido, D. R., Barraza-Jáuregui, G., & Siche, R. (2019). Biodegradable foam tray based on starches isolated from different Peruvian species. International Journal of Biological Macromolecules, 125, 800–807. https://doi.org/10.1016/j.ijbiomac.2018.12.111

Espina, M., Cruz-Tirado, J. P., & Siche, R. (2016). Mechanical properties of trays based on starch of native plant species and fiber of agroindustrial wastes. Scientia Agropecuaria, 07(02), 133–143. https://doi.org/10.17268/sci.agropecu.2016.02.06

Ferreira, A., Martins, J., Carvalho, L. H., & Magalhães, F. D. (2019). Biosourced Disposable Trays Made of Brewer’s Spent Grain and Potato Starch. Polymers, 11(5), 923. https://doi.org/10.3390/polym11050923

Ferreira, D. C. M., Molina, G., & Pelissari, F. M. (2020). Biodegradable trays based on cassava starch blended with agroindustrial residues. Composites Part B: Engineering, 183, 107682. https://doi.org/10.1016/j.compositesb.2019.107682

Hoyos Mireles, B. J., Cieza Díaz, E. del R., & Castro Medina, R. S. (2021). Ecological trays based on banana (Musa paradisiaca) and achira (Canna indica) leaf blades: Physical, mechanical and chemical characteristics. Agroindustrial Science, 11(1), 87–96. https://doi.org/10.17268/agroind.sci.2021.01.11

Kaisangsri, N., Kerdchoechuen, O., & Laohakunjit, N. (2014). Characterization of cassava starch based foam blended with plant proteins, kraft fiber, and palm oil. Carbohydrate Polymers, 110, 70–77. https://doi.org/10.1016/j.carbpol.2014.03.067

Keya, K. N., Kona, N. A., Koly, F. A., Maraz, K. M., Islam, M. N., & Khan, R. A. (2019). Natural fiber reinforced polymer composites: history, types, advantages, and applications. Materials Engineering Research, 1(2), 69–87. https://doi.org/10.25082/MER.2019.02.006

Machado, C. M., Benelli, P., & Tessaro, I. C. (2020). Study of interactions between cassava starch and peanut skin on biodegradable foams. International Journal of Biological Macromolecules, 147, 1343–1353. https://doi.org/10.1016/j.ijbiomac.2019.10.098

Moghaddam Fard, P., & Alkhansari, M. G. (2021). Innovative fire and water insulation foam using recycled plastic bags and expanded polystyrene (EPS). Construction and Building Materials, 305, 124785. https://doi.org/10.1016/j.conbuildmat.2021.124785

Nagaraj, C., Mishra, D., & Durga Prasad Reddy, J. (2020). Estimation of tensile properties of fabricated multi layered natural jute fiber reinforced E-glass composite material. Materials Today: Proceedings, 27, 1443–1448. https://doi.org/10.1016/j.matpr.2020.02.864

Ramos, E., Provost, K., Calle, S., & Zavala, K. (2020). The impact of asparagus supply chain quality management: An empirical research from Peru. International Journal of Supply Chain Management, 9(1). http://hdl.handle.net/10757/653827

Reis, M. O., Olivato, J. B., Bilck, A. P., Zanela, J., Grossmann, M. V. E., & Yamashita, F. (2018). Biodegradable trays of thermoplastic starch/poly (lactic acid) coated with beeswax. Industrial Crops and Products, 112, 481–487. https://doi.org/10.1016/j.indcrop.2017.12.045

Ruiz Quispe, G. F. (2018). Propuesta de mejora de métodos de trabajo en el proceso de producción de espárrago verde fresco para incrementar la productividad de la asociación agrícola Compositan Alto [Universidad Privada del Norte]. https://hdl.handle.net/11537/13349

Salgado, P. R., Schmidt, V. C., Molina Ortiz, S. E., Mauri, A. N., & Laurindo, J. B. (2008). Biodegradable foams based on cassava starch, sunflower proteins and cellulose fibers obtained by a baking process. Journal of Food Engineering, 85(3), 435–443. https://doi.org/10.1016/j.jfoodeng.2007.08.005

Sari, R. M., Torres, F. G., Troncoso, O. P., De‐la‐Torre, G. E., & Gea, S. (2021). Analysis and availability of lignocellulosic wastes: Assessments for Indonesia and Peru. Environmental Quality Management, 30(4), 71–82. https://doi.org/10.1002/tqem.21737

Soykeabkaew, N., Thanomsilp, C., & Suwantong, O. (2015). A review: Starch-based composite foams. Composites Part A: Applied Science and Manufacturing, 78, 246–263. https://doi.org/10.1016/j.compositesa.2015.08.014

Velasquez Barreto, F. F., & Bello-Pérez, L. A. (2021). Chemical, Structural, Technological Properties and Applications of Andean Tuber Starches: A Review. Food Reviews International, 1–16. https://doi.org/10.1080/87559129.2021.1933022

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Celestino Cabrera-Guevara, Yorli Diaz-Idrogo, Elmer Diaz-Diaz , Pedro Wilfredo Gamboa-Alarcón

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors retain their rights:

a. The authors retain their trademark and patent rights, as well as any process or procedure described in the article.

b. The authors retain the right to share, copy, distribute, execute and publicly communicate the article published in the Revista Amazónica de Ciencias Ambientales y Ecológicas (REACAE) (for example, place it in an institutional repository or publish it in a book), with an acknowledgment of its initial publication in the REACAE.

c. Authors retain the right to make a subsequent publication of their work, to use the article or any part of it (for example: a compilation of their works, notes for conferences, thesis, or for a book), provided that they indicate the source of publication (authors of the work, journal, volume, number and date).